Online Asset Management System

Bath Rugby Club

The Requirement: Easy & Accurate Asset Tracking & Management from the Shop to the Training Ground

Founded in 1865, Bath Rugby has had a long and illustrious 153 year history the club with wins that include the Anglo-Welsh Cup, the Heineken Cup and the European Challenge Cup. Indisputably at the top flight of English rugby, they play their domestic league matches in the English Premiership, the top flight of English rugby.

Bath Rugby Club management had the following objectives:

- To achieve an accurate, streamlined and digital asset management process for IT, Furniture, medical and rugby equipment across four locations within the club: the training ground, stadium, club shop and ticket office.

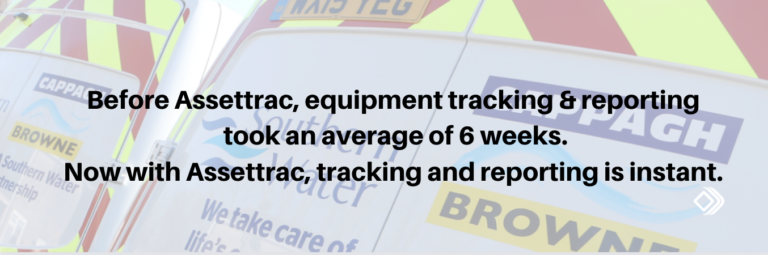

- To move away from using inaccurate, high-risk, administrative and restrictive spreadsheets to adopt easy-to-use, digital work processes with visibility, traceability and up-to-the-minute information.

- The system needed to be easy to update, add, dispose of items as part of on-going work processes all recorded and stored in one central area that was accessible by different areas of the business when required.

- Instant, 24/7 access from any location via browser or app with off-site data storage, security and back-up services.

- The system should be flexible and easy to manage, as well as fully scalable and adaptable for any future needs.

- It needed to track a complete electronic audit history for each asset throughout its lifecycle and to provide updates and alerts for maintenance, cleaning and inspections in real-time.

The Solution: Custom Asset Management System

Central Asset Management Portal + Custom Asset Tags

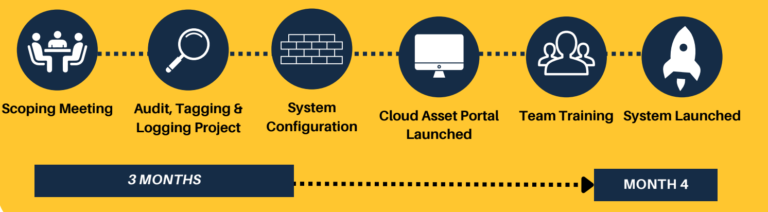

Assettrac customised and deployed a fully tailorable asset tracking and data management portal for the club that was intuitive and flexible to be able to be adapted in the future by Bath Rugby’s internal team. For the initial configuration, Assettrac worked with the staff at the club to make sure all aspects of information relating to their assets, and what they needed to track and report would be captured by their system.

Assettrac supplied hardware as well as custom asset tags that would be suitable to a variety of environments such as indoors versus outdoors, and that could be used on all types of equipment. Once the hardware was in place and tagging implemented, the centralised cloud system enabled specified personnel to manage their equipment, as well as allowing them to update and access the correct and latest details of any asset item at any of their specified locations. When the status of any item changes (such as a change in location, or taken for maintenance), staff can instantly update the details using a PC, laptop or handheld device.

Assettrac’s team of consultants provided implementation and full on-site training and implementation for administrators and other users to ensure a successful launch. While the system is intuitive, Assettrac supports Bath Rugby with unlimited access to customer support for any

additional assistance whenever it may be required.